Modern engineering continually seeks materials that offer optimal performance, efficiency, and adaptability. Among the most promising solutions emerging in recent years, aluminium perforated sheets have distinguished themselves as a transformative material with unparalleled potential across multiple industries.

The Engineering Marvel of Perforated Sheet Metal

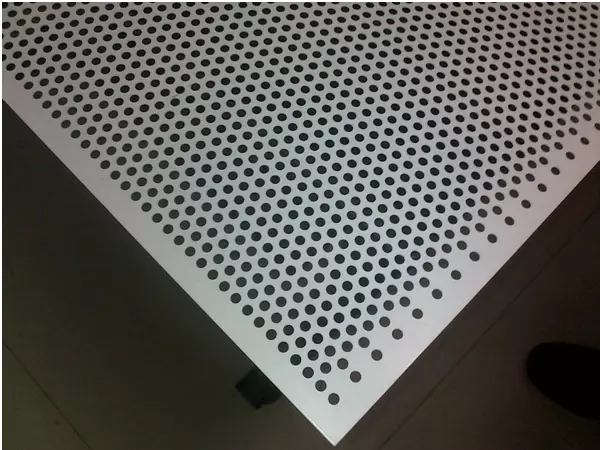

Perforated sheet metal represents a sophisticated engineering approach that transcends traditional solid metal applications. By strategically introducing precisely engineered holes into metal surfaces, engineers unlock a range of functional and aesthetic possibilities. Aluminium, with its inherent lightweight properties and exceptional durability, emerges as the ideal base material for these innovative sheets.

The perforation process involves carefully calculated patterns that serve multiple purposes simultaneously. These perforations can regulate airflow, reduce weight, enhance thermal management, and provide aesthetic flexibility. Unlike solid sheets, aluminium perforated sheets offer a unique combination of structural integrity and environmental interaction.

Versatility Across Industrial Applications

The adaptability of aluminium perforated sheets extends across diverse sectors. In architectural design, these sheets create stunning facades that balance aesthetics with functional performance. HVAC systems leverage their exceptional heat dissipation capabilities, while acoustic engineering utilises their sound-modulating properties to control noise levels in complex environments.

Manufacturing sectors appreciate the material’s ability to reduce overall product weight without compromising structural strength. aerospace, automotive, and construction industries have increasingly integrated these sheets into their design processes, recognising their potential to enhance performance and efficiency.

Technical Advantages of Aluminium Perforated Sheets

Several technical characteristics distinguish these sheets from traditional materials:

- Lightweight Composition: Aluminium’s natural low density ensures minimal weight without sacrificing durability.

- Corrosion Resistance: The material’s inherent protective properties make it suitable for challenging environmental conditions.

- Thermal Conductivity: Precise perforations enable superior heat management and air circulation.

- Customisation Potential: Hole sizes, patterns, and configurations can be tailored to specific engineering requirements.

Environmental and Economic Implications

The adoption of aluminium perforated sheets aligns with sustainable engineering practices. The material’s recyclability and energy-efficient production process contribute to reduced carbon footprints across manufacturing cycles. Moreover, the sheets’ ability to optimise thermal and acoustic performance translates into long-term energy savings.

Technological Innovations in Manufacturing

Emerging digital technologies are revolutionising the production of perforated sheet metal. Advanced computer numerical control (CNC) machines and laser cutting technologies now enable unprecedented precision in hole patterns and sheet configurations. Machine learning algorithms assist in optimising perforation designs, allowing engineers to simulate performance characteristics before physical production. 3D modelling and simulation tools have dramatically reduced prototyping time, enabling more complex and nuanced perforation patterns that were previously impossible to achieve. These technological advancements are pushing the boundaries of what can be accomplished with aluminium perforated sheets, opening new frontiers in material science and engineering design.

Future Perspectives in Engineering Design

As technological demands become increasingly complex, aluminium perforated sheets represent more than just a material—they embody a design philosophy prioritising intelligent, multipurpose solutions. Their potential continues to expand with advancements in precision manufacturing and computational design techniques.

Conclusion

The engineering landscape is witnessing a remarkable transformation, with materials like aluminium perforated sheets at the forefront of innovation. These sheets are not merely a product but a testament to human ingenuity—transforming simple metal into a sophisticated, multifunctional material that promises to shape the future of engineering design.

Dinco Trading LLC is facilitating this technological evolution by providing high-quality, precision-engineered perforated sheet solutions that meet the demanding specifications of modern industries.